One day it was very windy and all the tarps blew off the roof. Instead of trying to put them back on I decided it was time to put the roof membrane on to make things properly waterproof.

A straw bale studio

One day it was very windy and all the tarps blew off the roof. Instead of trying to put them back on I decided it was time to put the roof membrane on to make things properly waterproof.

The bottom of the roof was finished with a mixture of the OSB offcuts and pallets. This section doesn’t need to be wind/air tight as it’s an overhang, so it’s not over the livable area of the building.

I began this work once I received planning permission at the end of November 2022.

I also covered the roof with tarps during this period to try to minise the wear on the OSB. The roof OSB wasn’t SmartPly (though I was told it was) and it degrated in the weather much more quickly than SmartPly, so I wouldn’t get it again. I think it was Kronospan.

Fortunately my local farmer was happy to store my straw for me while the situation with the council was resolved. I went to help him with the harvest.

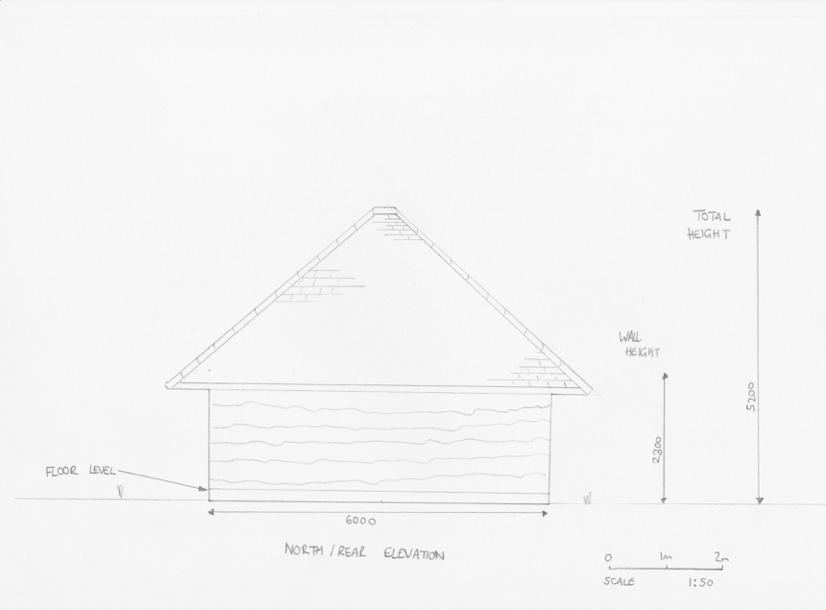

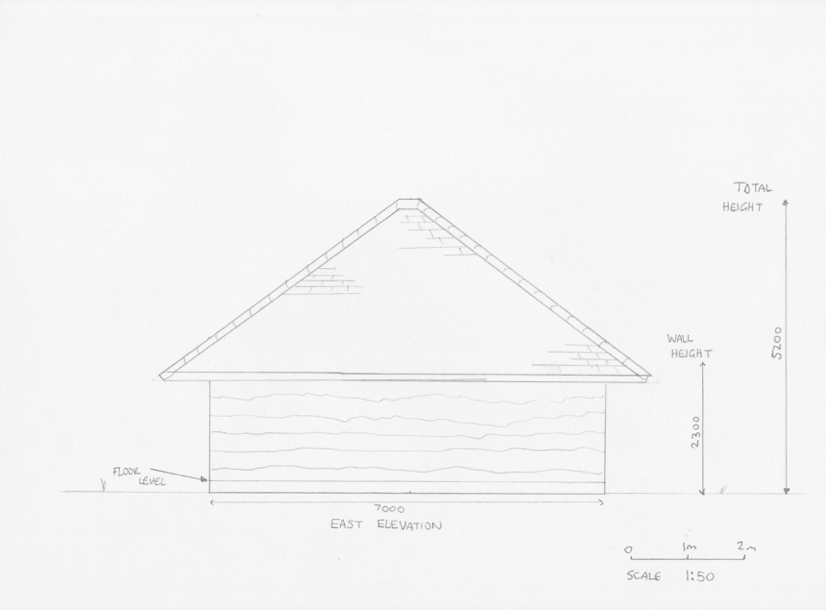

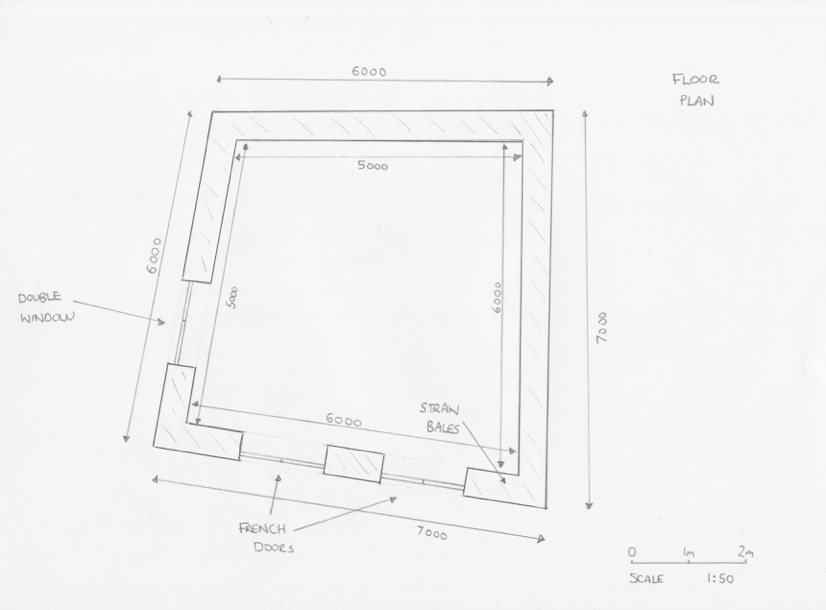

I’m not a huge fan of plans. I didn’t really draw any proper any plans until I had to apply for planning permission. At this point a good deal of the building was already in existence so the plans are more descriptive of what was there than of an intention.

The very top of the roof needed boarding with OSB but it was quite fiddly. The boards were very grippy so I didn’t need scaffolding or ropes.

This last picture was taken the day before I received a letter from the council advising me that the structure was too tall and would need to be dismantled. I stopped work on the building at this point until the dispute was resolved, so I lost about 4 months from this point.

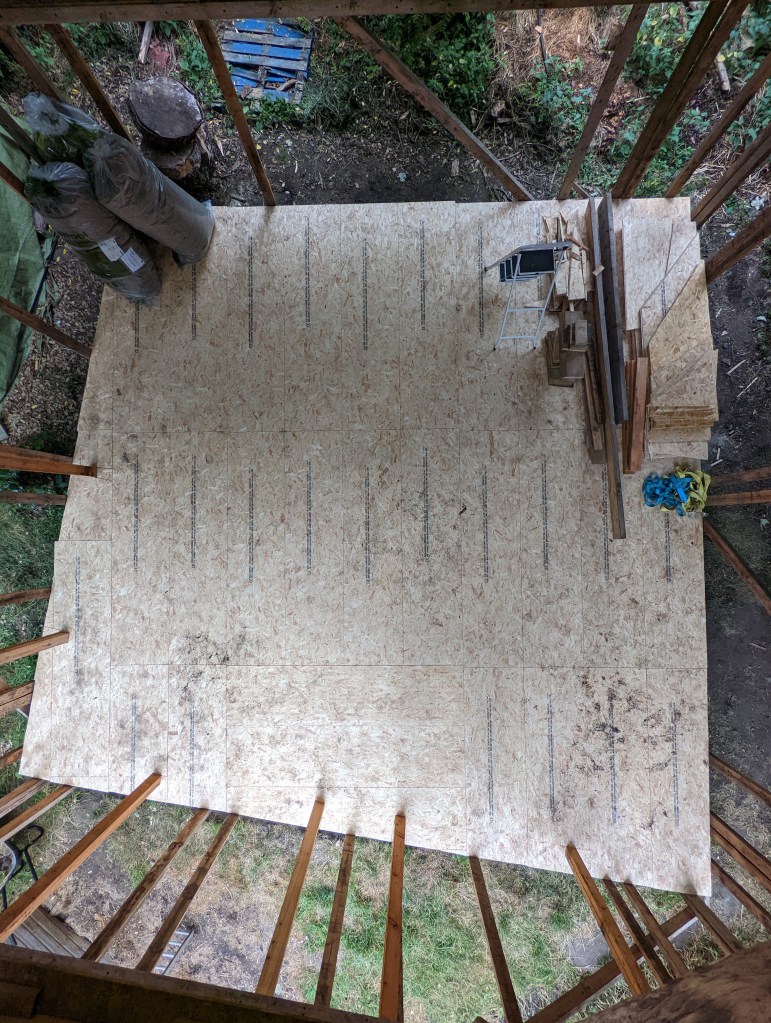

The base plate and floor was boarded over with 18mm SmartPly OSB. The plans specified that the base plate was boarded, and the the floor done later, but the advantage to doing it this way is that you get a continuous run of boards so a much more airtight floor.

Thanks to Andy for all the help with this. We did this on probably the hottest day of 2022.

The floor cavities were filled with FoamGlas chunks, and then a layer of sheep’s wool insulation.

The next step was to cover the roof with OSB. This will serve several functions. It keeps the rain off the building, so I can store the straw inside without it getting wet. It also adds racking strength to the roof. It also will enclose the sheep’s wool insulation making it more effective. It also gave us shelter from the sun while we were doing the floor.